新闻中心

NEWS CENTER

In the era of "double carbon", laser processing technology has become a rigid demand for green industry

- Categories:Industry News

- Author:Lao Niu

- Origin:Laser Manufacturing Network

- Time of issue:2022-05-27 10:27

- Views:

(Summary description)From December 8 to 10, 2021, the Central Economic Work Conference of the Communist Party of China was held in Beijing and proposed seven important policies for 2022, one of which is to correctly understand and grasp "carbon peaking" and "carbon neutrality".

In the era of "double carbon", laser processing technology has become a rigid demand for green industry

(Summary description)From December 8 to 10, 2021, the Central Economic Work Conference of the Communist Party of China was held in Beijing and proposed seven important policies for 2022, one of which is to correctly understand and grasp "carbon peaking" and "carbon neutrality".

- Categories:Industry News

- Author:Lao Niu

- Origin:Laser Manufacturing Network

- Time of issue:2022-05-27 10:27

- Views:

From December 8 to 10, 2021, the Central Economic Work Conference of the Communist Party of China was held in Beijing and proposed seven important policies for 2022, one of which is to correctly understand and grasp "carbon peaking" and "carbon neutrality".

Prior to this, the Ministry of Industry and Information Technology issued the "14th Five-Year Plan for Industrial Green Development" on December 3, 2021, which clearly proposed to build a green and low-carbon technology system and green manufacturing support around the implementation of the carbon peaking action in the industrial field. system, and promote the industrial transformation in six directions: high-end industrial structure, low-carbon energy consumption, recycling of resources, clean production process, green product supply, and digital production process.

Under the global theme of energy saving, environmental protection and new energy utilization, how can my country's industrial manufacturing walk out of the green road of environmental protection and energy saving? Today, let's take a look at the contribution of laser technology in environmental protection and industrial green development.

01 Laser is a faithful partner to achieve carbon peaking and carbon neutrality

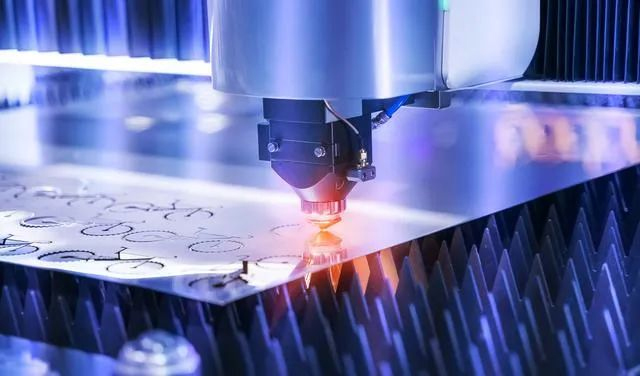

Laser is one of the great inventions of the 20th century. It has four characteristics: high brightness, good monochromaticity, coherence and directionality. Because laser processing is non-contact processing, there is no direct impact on the workpiece, so there is no mechanical deformation, no impact noise; no "tool" wear during laser processing, no "cutting force" acting on the workpiece; laser beam energy density during laser processing High, fast processing speed, and local processing, no or minimal impact on non-laser irradiated parts. Therefore, the heat affected zone is small, the thermal deformation of the workpiece is small, and the subsequent processing is minimal. Because the laser beam is easy to guide, focus and realize direction change, it is very easy to cooperate with the numerical control system to process complex workpieces.

Therefore, laser processing is an extremely flexible and convenient processing method, with high production efficiency, stable and reliable processing quality, and good economic and social benefits. No chemical pollution and environmental pollution, it is a faithful partner to achieve carbon peak and carbon neutrality.

02 Laser cleaning is a very environmentally friendly cleaning technology

With the advancement of science and technology, people have gradually explored various technologies that are conducive to environmental protection, and laser cleaning technology is one of them.

Laser cleaning is to use the high-energy laser beam to interact with the material to be removed on the surface of the workpiece, so that the attachments are instantly evaporated or peeled off to achieve the purpose of cleaning the workpiece. This processing technology does not require various chemical cleaning agents, and is green and pollution-free. And the scope of application is very wide, mainly used in surface paint removal and paint stripping treatment, surface oil, stain, dirt cleaning, surface coating, coating removal, welding surface / spray surface pretreatment, stone surface dust and attachment removal, rubber mold residues material cleaning, etc.

Traditional cleaning methods, including mechanical cleaning, chemical cleaning and ultrasonic cleaning, all produce pollutants to varying degrees, and their applications are greatly limited under the requirements of environmental protection and high precision. The laser cleaning process does not produce any harmful substances, which can be called quite environmentally friendly cleaning.

Compared with the traditional cleaning method, laser cleaning is a "green" cleaning method with incomparable advantages: no need to use any chemicals and cleaning fluids, and the cleaned waste is basically solid powder, small in size and easy to use. Storage, adsorption and recycling, no photochemical reaction, no noise and no environmental pollution. At the same time, it does not damage the health of operators, and it is easy to realize automatic control and remote remote cleaning.

03 Environmental Contribution of "Fiber Laser Technology"

As one of the promising new technologies in the 21st century, laser technology is also playing an important role in purifying the environment on which we live. The emergence and application of lasers has been called the third leap in human use of tools. In order to meet the needs of the transformation and upgrading of the manufacturing industry, laser technology will lead the manufacturing industry to develop in the direction of high efficiency, energy saving, environmental protection and intelligence.

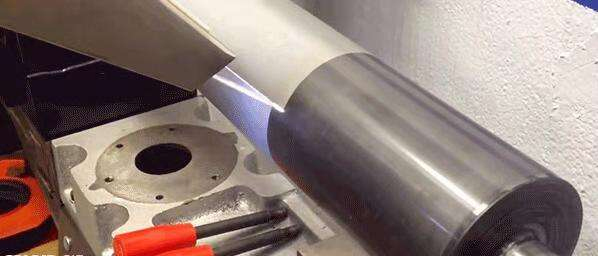

Fiber lasers have high electro-optical conversion efficiency. Compared with different lasers, in terms of electro-optical conversion rate: fiber lasers reach 30%, YAG solid-state lasers are only 3%, and CO2 lasers are 10%; the gain medium in traditional lasers must usually be cooled by water. . Fiber lasers use fiber as the gain medium, which has a large surface area/volume ratio, which makes it have very good heat dissipation performance. At the same time, the closed all-fiber structure ensures the stability of the laser cavity. Because of these unique characteristics of fiber lasers, their cooling requirements are greatly reduced. Low-power fiber lasers only need to use air cooling, replacing the water cooling requirements necessary for traditional lasers, thereby saving electricity and water. Contribute to reducing emissions.

04 Laser integrates energy saving, environmental protection, emission reduction and low carbon

In recent years, laser processing, as an advanced processing method, has gradually replaced a variety of traditional processing methods. In the fields of marking, welding, cutting, cleaning, cladding and additive manufacturing, laser processing has gradually demonstrated unparalleled advantages.

For example, with the development of the times, various laser cleaning technologies that are conducive to environmental protection have emerged; such as lidar, which can accurately analyze the geographic location, pollution area, and frequency of pollution sources, speculate pollution sources and pollution causes, and effectively improve air pollution control Efficiency; laser removal, which is more efficient and less expensive than traditional methods; laser lighting that is brighter than LED while being smaller, more energy-efficient, farther, and more power-efficient; and an alternative to electroplating The technology has now become a consensus in the industry. Its features of low cost, zero pollution, long life and low energy consumption are recognized by the market, such as laser cladding technology, which are all low-carbon technologies that save energy, protect the environment and reduce emissions.

Achieving carbon peaking and carbon neutrality is an inherent requirement for promoting high-quality development, which must be correctly understood and unswervingly advanced. To this end, we must unswervingly follow the ecological priority, green and low-carbon high-quality development path, seize the critical period and window period for making good use of the "14th Five-Year Plan" carbon peak, and resolutely shoulder the political responsibility of environmental protection. Take the initiative to take responsibility and act actively, and make new contributions to accelerating the construction of a beautiful Greater China with blue sky, beautiful land and beautiful water.

Source: Laser Manufacturing Network Editor: Lao Niu

In the era of "double carbon", laser processing technology has become a rigid demand for green industry

Laser processing market segment development and future development prospect forecast

The National Health Commission issued a document restricting the use of imported medical consumables!

Concentrate on the real effect, focus on the true feelings - welcome the visit of President Zhou of the SMT Association and his party to jointly help the electronic intelligent manufacturing industry flourish!

Follow Us

Contact Us

Headquarters address: No. 335 Jinyang Road (No. 2 Jinxia Road), Lujia Town, Kunshan, Jiangsu Province

Office in Southern China: Room 210, Wangjiao Mingqihui, No. 2 Hengzeng Road, Chang'an Town, Dongguan, Guangdong Province