About Us

- Categories:Innovative service platform for high-end manufacturing system of medical equipment

- Time of issue:2022-04-02 10:39:42

- Views:0

Development Strategy

Strengthen the combination of medicine and industry, and devote itself to providing a closed-loop development platform for medical device pre-research design, engineering verification, and clinical testing from the perspective of new technology and engineering technology innovation service system, and consolidate the foundation of medical device innovation and design. Collaborate with medical experts, medical device R&D team, and medical device engineering production team to break through the barriers to cooperation between demand, design, production, iteration, and product finalization, and shorten the development cycle of medical devices

Medical Specialist

- Communication and discussion of clinical needs

- The effectiveness of medical devices in solving practical problems

- Medical Device Reliability Evaluation

- Medical device operability evaluation

- Clinical trials and follow-up feedback

Medical Device R&d Enterprises And Scientific Research Units

- Research and development needs analysis and engineering verification implementation plan

- Comparison of sample iterative development and clinical trial tracking

- Continuous improvement and product finalization

- Product compliance, legality registration

- Product mass production plan

Innovative Service Platform for Advanced Manufacturing System of Medical Devices

- Medical Device Manufacturing Systems and Process Engineering Technology Alliance

- 30 professional medical device processing engineering laboratories

- Jointly set up an engineering test platform with scientific research units

- Engineering and technical personnel training base and engineering technology forum

- Professional technical forum and engineering practice base of scientific research institutions

Changes in Market Demand

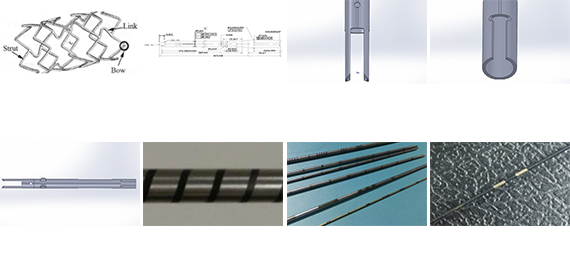

Highly Flexible Processing

Process flexibility: centripetal, vertical, compound features, dry cutting, wet cutting, precise parameter control...;

Diversified materials and shapes: metal & non-metallic plane & equal diameter tube & reducer tube compatible processing...;

Micro & large size instrument processing: fine processing of intracranial instruments and arterial vascular instruments...;

Diversified processes: cutting, drilling, grooving, welding, marking...;

Process automation: automatic loading and unloading, automatic feeding and processing, processing simulation, online measurement, positioning and monitoring...;

Precision Service

Diversified service modes: equipment sales, leasing, upgrading of old equipment..., new product aided design, proofing, small batches, batch OEM...;

One-stop processing service: to meet the expansion services of related materials, processing, and measurement other than laser micro-processing;

Cost-effective personalized service: provide cost-effective laser micromachining system solutions for market segments;

Soft power training: theoretical knowledge and practical training services of system & process & market segment information & professional technology...;

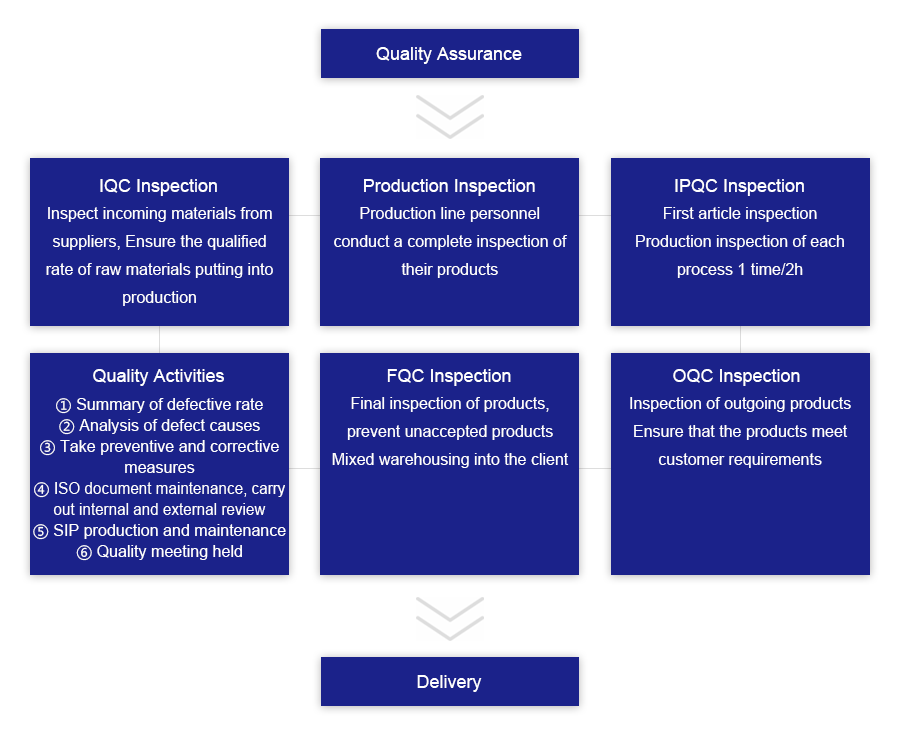

Engineering Management Service System

Medical equipment advanced manufacturing system innovation service platform ERP management system

01 Craft proofing

02 Product measurement

03 Product post-processing

Company Culture

In ancient times there was a saying of nine qi: "talent, clear, benevolent, ambitious, harmonious, confident, righteous, backbone, and grand". The connotation is profound, and it deeply inherits the essence of Chinese culture. Take the meaning of "humility and virtue, lofty aspirations, and integrity".

Follow Us

Contact Us

Headquarters address: No. 335 Jinyang Road (No. 2 Jinxia Road), Lujia Town, Kunshan, Jiangsu Province

Office in Southern China: Room 210, Wangjiao Mingqihui, No. 2 Hengzeng Road, Chang'an Town, Dongguan, Guangdong Province